Elevate Your Building And Construction Process With the Strategic Insights of Concrete Scanning for Boosted Performance

In the realm of contemporary building and construction methods, the mission for effectiveness and precision is critical. Accepting innovative technologies has actually ended up being a keystone for accomplishing these objectives. One such modern technology that has transformed the building sector is concrete scanning. By utilizing the critical insights given by concrete scanning, building and construction professionals can unlock a realm of improved efficiency and streamlined procedures. The implications of integrating concrete scanning go far past surface-level advantages, supplying a profound effect on job end results.

Advantages of Concrete Scanning

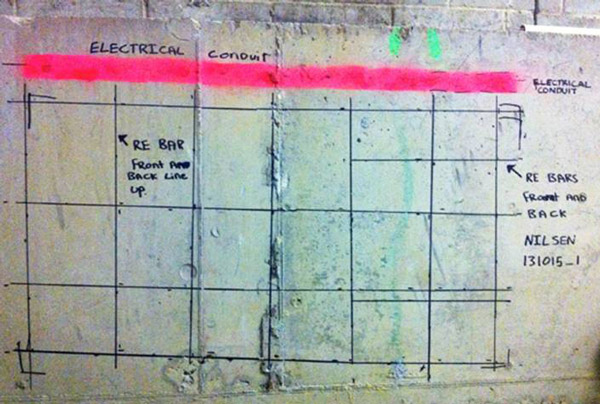

Enhancing task efficiency and security, concrete scanning provides a non-destructive method for identifying covert items within concrete structures. By making use of innovations such as ground-penetrating radar (GPR) and concrete x-ray imaging, construction teams can precisely situate rebar, post-tension cable televisions, electrical channels, and various other blockages prior to drilling, reducing, or coring into concrete.

The advantages of concrete scanning are various. Building and construction sites can be complex atmospheres, and recognizing what exists beneath the surface area can stop crashes and injuries.

Additionally, concrete scanning advertises overall job effectiveness by simplifying workflows and preventing rework. By identifying prospective concerns at an early stage, groups can adjust their plans proactively, saving time and resources in the long run. Fundamentally, the adoption of concrete scanning technologies is a tactical investment that pays returns in terms of safety, cost-effectiveness, and efficiency.

Technology Combination for Performance

Concrete scanning's capability to enhance process and boost task performance can be more optimized via strategic integration of sophisticated technologies. By including Building Info Modeling (BIM) software right into concrete scanning processes, construction groups can attain a higher level of accuracy and control. In addition, the combination of Enhanced Truth (AR) innovation with concrete scanning can boost on-site visualization, permitting task managers and workers to overlay electronic details onto the physical atmosphere in actual time.

Avoiding Expensive Errors

How can thorough interest to detail throughout concrete scanning procedures assist building teams in stopping pricey mistakes? Concrete scanning plays an essential role in identifying prospective issues prior to they escalate right into expensive errors. By making use of advanced scanning technologies such as Ground Penetrating Radar (GPR) and electro-magnetic induction, construction teams can precisely identify rebar, energies, voids, and various other obstructions within concrete structures. This level of accuracy allows job managers to make informed choices concerning the design and layout of their building strategies, decreasing the threat of unexpected damage to critical infrastructure during the building process. Furthermore, concrete scanning assists in guaranteeing structural stability by recognizing weak points or flaws in the concrete at an early stage, permitting for prompt repair services and alterations. By proactively attending to these problems, construction teams can prevent expensive mistakes such as rework, delays, or safety dangers that might occur from ignored inconsistencies in the concrete structure. Inevitably, purchasing extensive concrete scanning procedures proves to be an affordable strategy in the future, conserving both time and resources while improving total project performance and high quality.

Enhancing Project Management

Meticulous attention to detail throughout concrete scanning refines not only helps in staying clear of pricey errors yet likewise lays a solid structure for effective job administration in building and construction undertakings. By integrating concrete scanning innovation right into project monitoring strategies, construction teams can see this site simplify workflows, boost communication, and guarantee that tasks remain on track.

Concrete scanning provides useful insights right into the structural integrity of existing components, permitting job managers to make informed choices relating to design adjustments or building and construction sequences. This proactive technique decreases the threat of unexpected hold-ups or rework, inevitably conserving time and sources. In addition, the data obtained from concrete scanning can be integrated right into Building Information Modeling (BIM) systems, making it possible for real-time partnership and coordination among different stakeholders.

Furthermore, concrete scanning aids job supervisors identify potential threats or challenges before they escalate right into larger problems, advertising a more secure job setting for all entailed. With boosted presence and precision given by concrete scanning technology, job managers can successfully plan, keep an eye on, and execute building and construction jobs with greater effectiveness and confidence.

Making Best Use Of Performance

One essential facet of maximizing performance is via the fostering of concrete scanning technology. By using ground-penetrating radar (GPR) and various other scanning approaches, building teams can accurately situate rebar, conduits, and various other subsurface components, lessening the danger of pricey errors and delays throughout excavation and boring.

In addition, embracing Building Details Modeling (BIM) software application can considerably boost productivity by producing comprehensive 3D models that enhance job visualization and control amongst various trades. BIM permits for better clash detection, making it possible for issues to be determined and fixed before construction even starts, conserving time and sources in the lengthy run.

Implementing a lean building technique, which concentrates on getting rid of waste and enhancing performance across all job stages, is an additional reliable method for making advice the most of performance. By promoting cooperation, interaction, and constant enhancement, building and construction groups can work extra cohesively towards accomplishing job goals in a effective and structured way.

Conclusion

To conclude, the critical implementation of concrete scanning in the construction procedure supplies numerous advantages, consisting of enhanced efficiency, expense savings, enhanced job management, and enhanced efficiency. By integrating this modern technology, construction teams can stay clear of pricey errors, streamline their procedures, and maximize their total project output. Concrete scanning is a valuable device that can raise the building procedure and cause more rewarding and effective end results.